Fixing & Working

Want to fix our prefinished ariaply or iHoop? Use our patented invisible fixing system shadowFIX with X-Tack adhesive.

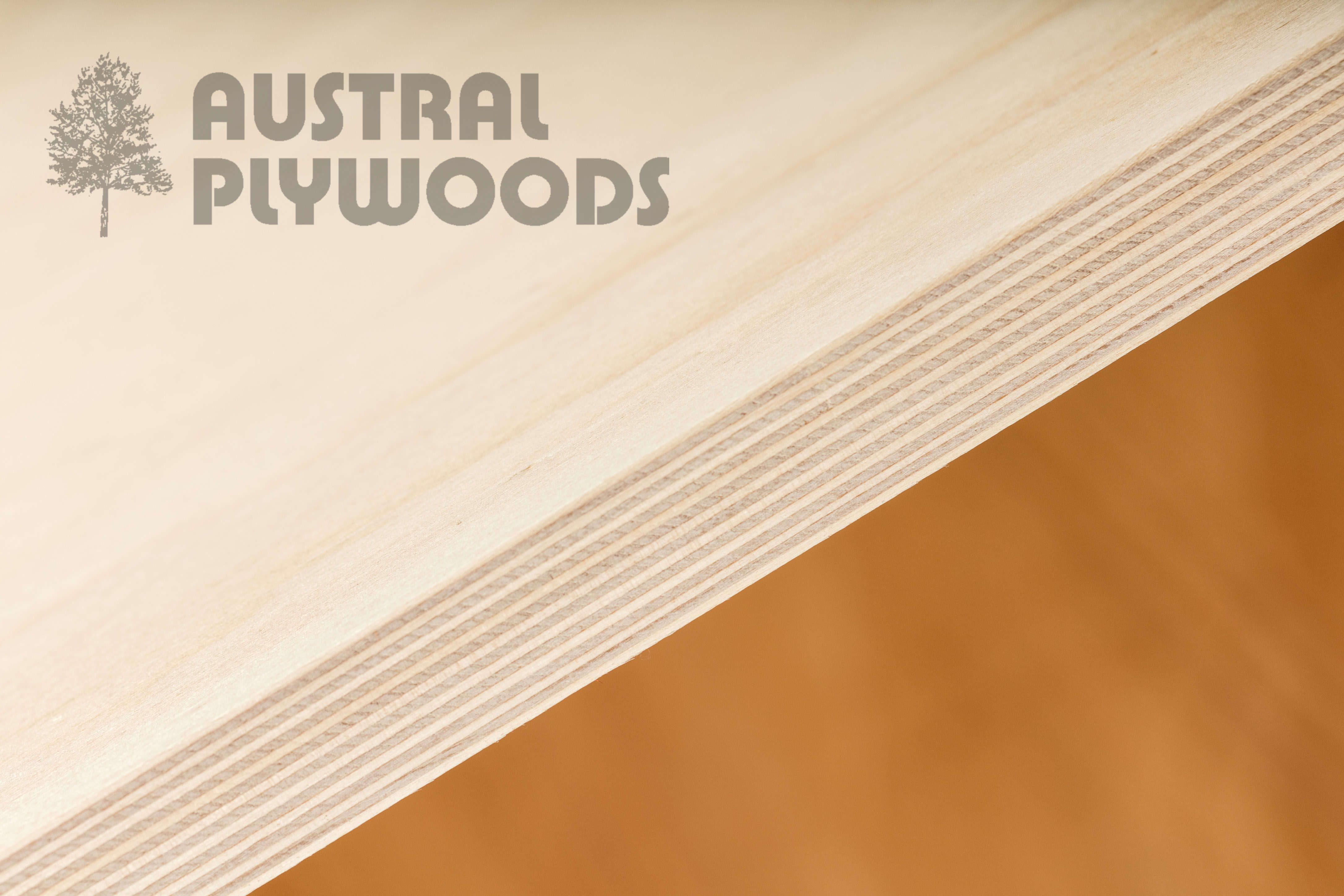

EWPAA product certified plywood and LVL can be sawn, drilled, shaped, nailed, screwed and glued like regular wood, using simple carpenter's tools. Because of the cross laminated construction of plywood, it can be nailed close to the edge (within 7mm for plywoods up to 7mm thick and 10-12mm for thicker plywoods), without fear of splitting. This characteristic is used to advantage in applications such as plywood bracing and nailed plywood webbed beams.

Standard plywood products are manufactured with a "balanced" construction to build in panel stability. No plywood panel, however, will stay entirely flat under all ambient conditions if left free to move. Warping, bowing and twisting can occur due to moisture imbalances, unbalanced laminates or paint coats or unbalanced stresses. It is strongly recommended therefore that regardless of thickness, plywood should always be positively fixed to supports.

Depending on the type of supports, plywood can be fixed with standard fasteners. Full fixing requirements are detailed for plywood bracing, flooring, roofing, claddings, linings and webbed beams in EWPAA Technical literature. Plywood to timber support connections can be made with standard nails and wood screws. In arduous applications or where low joint strength species are used as supports such as plantation pines, oregon and spruce pine fir (SPF), deformed shank nails are recommended.

Straightening systems for timber doors are available, to prevent possible warping and bowing. Planofit by Häfele is an example (view datasheet).

The availability of reliable engineering data on nailed timber to plywood joints in AS 1720 and the development of nailing guns has revolutionised the potential of plywood in fabricated components such as webbed channel and box beams, gussets in portal frames and stressed skinned panels used in tableforms and domestic floors. Safe, economical and extremely reliable joints can now be site manufactured with machine driven nails.

In plywood to steel support connections self drilling and tapping screws are recommended.

It is often beneficial in applications such as flooring to use a structural elastomeric adhesive as well as mechanical fasteners to eliminate such occurrences as squeaky floors.

Bending plywood is relatively simple. Plywoods with Type A bond phenolic glue lines can be soaked or steamed to assist bending. Minimum safe bending radii are obtainable from the EWPAA technical literature. It is not possible to obtain a compound curve when bending flat plywood panels.

Moulded plywood is required for unsupported bends or compound curves. Moulding is controlled in the manufacturing process. A small number of specialised manufacturers produce moulded plywood.

Factory manufactured scarf jointed plywood is available from limited sources. The scarf joint is fabricated with the same bond durability and quality as the plywood. Testing in CSIRO has shown that the panel stiffness (MoE) is unaffected by scarfing. Allowable bending stresses must be reduced by a 0.8 multiplying factor. Compression and shear stresses are also unaffected.

Glue Fixing

The control required for successful gluing with resorcinol type adhesives precludes its recommendation for site gluing application. These rigid permanent adhesives have no gap filling properties and require 0.8 to 1.0 MPa pressure to bring surfaces together for successful bonding. This is almost impossible to achieve on site. Additionally the use of resorcinol formaldehyde adhesives requires close control over timber moisture content, temperature and open and closed assembly times all of which may be difficult or impossible to control on site. Resorcinol adhesives must only be used under factory type control. A good rule is to use mechanical fixing for site connection and resorcinol adhesive where fabrication is carried out under factory conditions.

Structural elastomerics are very tolerant and can be used on site to fix flooring panels to joists.

Storage of plywood and LVL should always be in a dry sheltered position, covered from sunlight. Plywood panels should always be stored flat on rails, with the top panel protected from changes in moisture conditions. Do not lean panels against a wall or the side of the rack for any period of time.

Extract from the EWPAA Publication "Facts About Plywood", courtesy of the EWPAA.